Introduction to MLC Lazer Metal and its technology

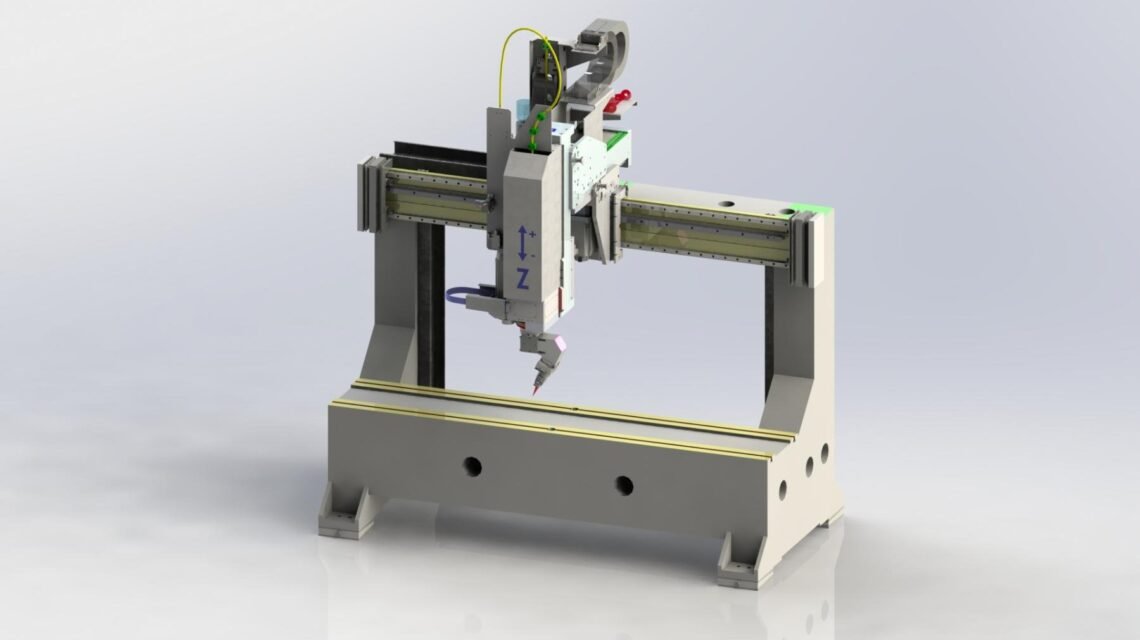

At MLC Lazer Metal, a company embracing the future of cutting precision with world-class laser technology, metalworking is taken to a new level with its advanced approach to cutting and unparalleled quality. The context of MLC Lazer Metal will transform everything, be it a small business or a prominent manufacturer, as it allows us to utilize all available possibilities in the industry.

With the world of metal fabrication advancing, MLC Lazer Metal is setting the standard for excellence in precision cutting. Gone are the days when intricate designs had misalignments, as now they are cut with laser-like precision. Now that we have examined them let’s explore how various industries can benefit from their services while maintaining uncompromised high quality.

Table of Contents

Advantages of precision cutting in metal fabrication

Precision cutting in metal fabrication is a game changer. It allows for intricate designs and complex shapes that traditional methods can’t achieve.

This technology ensures clean edges and minimal waste, which saves costs. The accuracy of precision cutting reduces the need for extensive finishing processes, speeding up production times considerably.

Moreover, it enhances consistency across multiple pieces. Every item produced meets exact specifications, leading to improved quality control.

The adaptability of precision cutting also implies that it may be applied to different materials, such as stainless steel and aluminium, making it very useful for other purposes. This adaptability opens doors for innovation in design and function.

Companies utilizing precision cutting benefit from higher customer satisfaction due to superior product quality and reliability in delivery timelines.

The various industries that benefit from MLC Lazer Metal’s services

MLC Lazer Metal serves diverse industries, each benefiting from its precision cutting technology. Great care is needed when crafting each component since the auto industry relies on careful design and manufacture of parts. MLC’s advanced methods ensure parts fit perfectly and perform reliably.

Aerospace is another critical industry where precision matters immensely. Components must withstand extreme conditions, making accuracy essential in the manufacturing process.

Construction also sees significant advantages from MLC Lazer Metal services. Precision-cut structural elements lead to safer and more durable builds, improving overall project integrity.

The electronics field demands intricate designs for circuit boards and housings. MLC’s laser capabilities allow for complex shapes without compromising quality or efficiency.

Medical device manufacturing requires exceptional safety and functionality standards. MLC provides the necessary reliability through precise cutting techniques tailored to this sensitive market.

These sectors showcase just a fraction of how versatile and impactful MLC Lazer Metal’s services can be across various applications.

Case studies showcasing MLC Lazer Metal’s precision cutting capabilities

MLC Lazer Metal has delivered exceptional results across various projects, showcasing its precision cutting capabilities. One notable case involved a high-end automotive manufacturer seeking intricate cut parts for their latest model. MLC’s advanced technology ensured flawless edges and minimal material waste, enhancing the overall design.

Another example comes from the aerospace sector. A client required lightweight components with exact specifications to meet stringent safety standards. With state-of-the-art laser systems, MLC Lazer Metal produced parts that met every requirement while significantly reducing lead times.

An artist needed detailed metalwork for a public installation in the architectural field. The precise cuts created by MLC allowed for stunning designs that transformed the space into a visual masterpiece.

These examples illustrate how diverse industries leverage MLC’s expertise in precision cutting to achieve superior quality and efficiency in their projects.

How MLC Lazer Metal maintains quality and accuracy in its processes

Quality and precision achieved on every project ensure MLC Lazer Metal is at the industry’s cutting edge. Each of the laser cut machines is outfitted with sophisticated sensors that track the accuracy of each cut as it happens. This allows for immediate adjustments, minimizing errors.

Skilled technicians also play a critical role. They meticulously calibrate the equipment before each job, guaranteeing optimal performance tailored to specific materials and designs. Regular maintenance checks keep machinery operating at peak efficiency.

Additionally, MLC emphasizes rigorous quality control measures throughout the fabrication process. Each piece undergoes thorough inspections against strict specifications before it leaves the facility, ensuring only flawless products reach clients.

The commitment to continuous improvement is also evident. MLC regularly invests in employee training and new technologies, enhancing its processes further while adapting to industry advancements.

The future of precision cutting technology and its impact on the metal fabrication industry

The future of precision cutting technology is bright and filled with promise. Fibre laser systems are emerging at an alarming rate. These advances boost speed and accuracy while allowing for more intricate designs.

As automation grows, the integration of AI will further improve processes. This shift not only boosts efficiency but also significantly reduces human error.

Sustainability is another key focus area. Advanced technologies minimize waste during cutting, aligning with global environmental goals.

Moreover, collaboration between industries will drive advancements in materials being used for fabrication. Lightweight yet durable options can lead to new applications across various sectors.

All these developments signal a transformation within the metal fabrication landscape, positioning companies like MLC Lazer Metal at the forefront of this evolution.

Conclusion:

MLC Lazer Metal stands at the forefront of precision cutting technology, offering unmatched quality for various industries. Its sophisticated methods ensure that every cut is accurate and tailored to meet specific needs. As metal fabrication evolves, MLC Lazer Metal remains committed to pushing boundaries and enhancing capabilities.

The future looks bright, with technological advancements promising even more efficiency and precision. This will have a significant impact on the metal fabrication industry as companies strive for higher standards and better results.

For businesses seeking reliable partners in precision cutting, MLC Lazer Metal represents an exceptional choice that prioritizes quality, innovation, and customer satisfaction. Embracing these technologies means embracing progress within a competitive landscape where excellence is key.

FAQs:

Q: What is MLC Lazer Metal well known for?

A: MLC Lazer Metal is well known for delivering precision cutting technology that consistently produces top-notch metal fabrication.

Q: In what ways does MLC Lazer Metal increase production proficiency?

A: MLC Lazer Metal increases production proficiency through precision cutting, which diminishes waste and lowers the need for extensive finishing processes.

Q: What services does MLC Lazer Metal render, and in what industries?

A: MLC Lazer Metal renders services in many industries, such as automotive, aerospace, construction, electronics, and medical device manufacturing.

Q: What are the merits of precision cutting for MLC Lazer Metal?

A: The merits of precision cutting for MLC Lazer Metal include incorporating detailed designs, maintaining clean edges, and replicating consistent quality on all pieces.

Q: How are the standards of MLC Lazer Metal retained during the cutting process?

A: MLC Lazer Metal maintains its high standards through the use of advanced sensors, qualified personnel, and stringent quality control.

Q: How does technology impact MLC Lazer Metal’s operations?

A: Technology impacts MLC Lazer Metal’s operations. Advanced laser systems are employed, which increases the accuracy and efficiency of metal cutting.

Q: Can MLC Lazer Metal cut different materials?

A: MLC Lazer Metal can efficiently and accurately cut multiple materials ranging from stainless steel to aluminium.

Q: How does MLC Lazer Metal further the sustainability of the metal fabrication industry?

A: MLC Lazer Metal furthers sustainability by reducing waste created during cutting and investing in environmentally friendly technologies.

Q: What is the expectation for the future of MLC Lazer Metal’s technology?

A: The expectation of the future for MLC Lazer Metal’s technology is encouraging as the development of AI and fibre laser systems enhances the machines’ speed, accuracy and design possibilities.

Q: Why should businesses select MLC Lazer Metal for the cutting services?

A: MLC Lazer Metal’s precision cutting services have made the company a favourite among businesses due to its low tolerance for defects and innovative technologies.

127.0.0.1:62893 Solved: Fixing Common Connection Errors

127.0.0.1:62893 Solved: Fixing Common Connection Errors  fintechzoom .io: Making Money Management Simple & Smart

fintechzoom .io: Making Money Management Simple & Smart  MYLT34 Unveiled: Unlocking Business Success

MYLT34 Unveiled: Unlocking Business Success  Antarvwsna: Embracing a Revolutionary Technology

Antarvwsna: Embracing a Revolutionary Technology  Jonathonspire: Unveiling the Power of Innovation

Jonathonspire: Unveiling the Power of Innovation  techdae.frl: A Positive Outlook on the Future

techdae.frl: A Positive Outlook on the Future